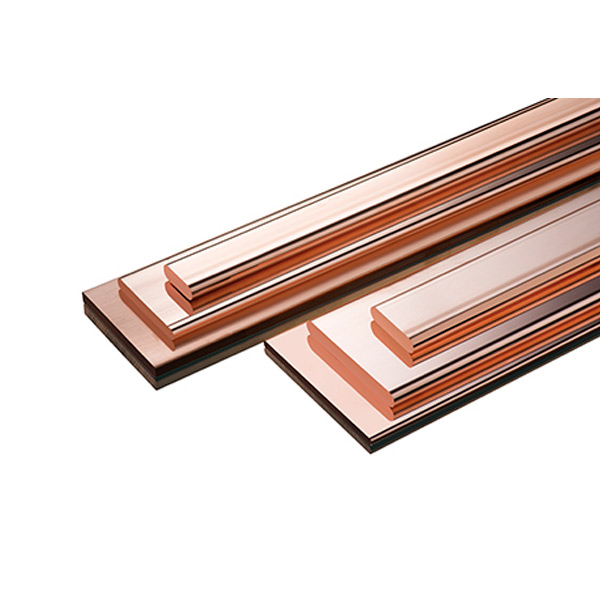

An air conditioner is mainly composed of a compressor, a radiator, and an automatic control system. The copper tube in the radiator is called the “blood vessel” of the air conditioner in the industry. The quality of the “blood vessel” will directly determine the quality of the air conditioner. Below we will combine production practice to talk about the problems that often occur in the use of air-conditioning and refrigeration copper pipes.

Copper pipe is an important raw material for refrigeration equipment, and it has two main applications:

① Make a heat exchanger. Such as the commonly used evaporator and condenser, commonly known as “two devices”.

② Make connecting pipe fittings. Regardless of the use, it is the passage of the refrigerant, and its role is very important.

On the one hand, copper tube manufacturers should provide high-quality copper tubes, and on the other hand, air-conditioning and refrigeration companies should use copper tubes properly.

1. Several states of copper pipe external supply

Coiled pipe: At present, it is mainly used for two main pipes, connecting pipes, pipe fittings, etc. Features: easy to transport, users are not limited by the length in the process of use.

Mosquito coil tray: mainly used in the maintenance market. Features: easy to use.

Straight pipe: mainly used for central air conditioning, and connecting pipe. Features: It is inconvenient to transport, and there are length limitations in use.

2. Problems that often occur in the use of copper pipes: leakage of copper pipes

Leakage of copper pipes is a fatal flaw in air conditioners. Once leaked, all the refrigerants in the air conditioner will overflow. The air conditioner lacks a heat transfer medium, and the machine will fail. The reasons for the leakage of copper pipes are more complicated. Below we will explain the reasons for frequent leakage.

Manufacturing reasons

① Eddy current flaw detection missed inspection. GB stipulates that 100% eddy current testing must be carried out for copper tubes, and it also stipulates the diameter of artificial defects (holes) on the sample tubes used for checking flaw detectors, to ensure the sensitivity of eddy current testing and to prevent excessive defects from being missed.

This requirement can be fully guaranteed in regular large-scale copper pipe factories. Because flaw detection is online, this online eddy current flaw detection ensures that all lengths of the pipe are subject to eddy current testing, which is 100% flaw detection.

Some copper pipe factories are not like this, do not go through eddy current flaw detection, or use a low-standard eddy current flaw detector for random inspection. In this way, there are defects in the copper pipes that exceed the standard and are missed or undetected, resulting in leakage of the air conditioner when the user uses it.

② Eddy’s current inspection detects defects, but the copper tube surface is not marked or the marking is inaccurate and unclear. In the production process of copper tubes, the defects detected by eddy current inspection require that ink marks be used to cover the defects that exceed the standard so that the user can remove the defective copper tubes during use.

However, due to the insufficient adhesion of the ink selected by the manufacturer in the production process, improper adjustment of the inkjet spray gun, incomplete drying, and high-temperature fading of the ink components, the user cannot detect the eddy current flaw detection during use. Once the defective copper pipe is used in the air conditioner, it is bound to cause leakage.

Reasons for use by users

The user uses the copper tube, like level wound copper tube , to make two processes: cutting, bending, expanding, cleaning, welding, and pressure testing.

① Misuse of defective tubes detected by eddy current inspection. Under normal copper tube production conditions, copper tube eddy current inspection not only marks the number of wound spots on each coil but also paints black marks on the wound spots, so that users can identify and pick out this “black tube” in use.

Air-conditioning and refrigeration enterprises should make it clear to operating workers, especially new workers, in order to prevent such injured pipes from being installed on air-conditioning and refrigeration units.

We have found this problem many times when we go to customer service, and some workers ask us what is the black on the pipe. Sometimes when dissecting unqualified products, the air-conditioning refrigeration unit leaks due to the “black pipe” being installed on the product.

② processing problems. In the process of forming the two devices, the air-conditioning main tube has to go through such links as bending, expanding, flaring, and welding.

In the process of bending the pipe, the bending part is subject to local stress, resulting in local overstretching, resulting in cracks, dark cracks, and other problems. Once filled with refrigerant, refrigerant leakage often occurs here.

Principles of Air Conditioning and Refrigeration

When the system is working, the compressor sucks the low-temperature and low-pressure refrigerant vapor generated by the evaporator into the cylinder, and after being compressed by the compressor, when the pressure rises (and the temperature also rises) to a slightly greater than the pressure in the condenser, the refrigerant is put into the cylinder. The high pressure refrigerated vapor is discharged to the condenser.

In the condensation, the high-temperature and high-pressure refrigerant vapor exchanges heat with air (or room temperature water) at a lower temperature and condenses into a liquid refrigerant. At this time, the liquid refrigerant is cooled (depressurized) by the expansion valve and then enters the evaporator, where it evaporates. After absorbing the heat of the object being cooled, it vaporizes. In this way, the cooled object is cooled and the refrigerant vapor is sucked away by the compressor. Therefore, a cycle is completed in the refrigeration system through the four processes of compression, condensation, expansion and evaporation.

Copper pipes for air conditioners play an important role in the refrigeration process of air conditioners. A copper pipe with high thermal conductivity and stable quality is an essential part of a high-quality air conditioner.

The air conditioning pipe fittings are the air-conditioning refrigerant pipe, which plays the role of a refrigeration pipe.

The air conditioning refrigerant pipe refers to the pipe connecting the main refrigeration components such as heat exchangers, valves, compressors, etc., through which the refrigerant flows in the air conditioning system. Usually copper pipes are used. The refrigerant line is long. If the refrigerant pipeline is too long, the expansion valve generally adopts the external balance mode to cope with the pressure drop from the inlet of the evaporator to the suction port of the compressor. The refrigerant pipeline is a pressure-bearing component, and its burst pressure should be more than 5 times the operating pressure, or more than 3 times the maximum possible pressure.

The copper pipe is hard in texture, not easy to corrode, and resistant to high temperature and high pressure, and can be used in a variety of environments. Compared with this, the shortcomings of many other pipes are obvious. For example, the galvanized steel pipes used in residential buildings in the past are very easy to corrode, and problems such as yellowing of tap water and small water flow will occur after a short period of use. There are also some materials whose strength will decrease rapidly at high temperature, which will cause unsafe hazard when used in hot water pipes. The melting point of copper is as high as 1083 degrees Celsius, and the temperature of the hot water system is negligible for copper pipes.

The chemical properties of copper are stable, and it combines cold resistance, heat resistance, pressure resistance, corrosion resistance and fire resistance (the melting point of copper is as high as 1083 degrees Celsius), which can be used for a long time in different environments.

The copper pipe products produced by Loong Copper have excellent performance and stable quality, and are the copper pipe brand recognized by the world’s first-class air conditioner manufacturers.

High-quality copper pipes can last as long as a building, if not longer.