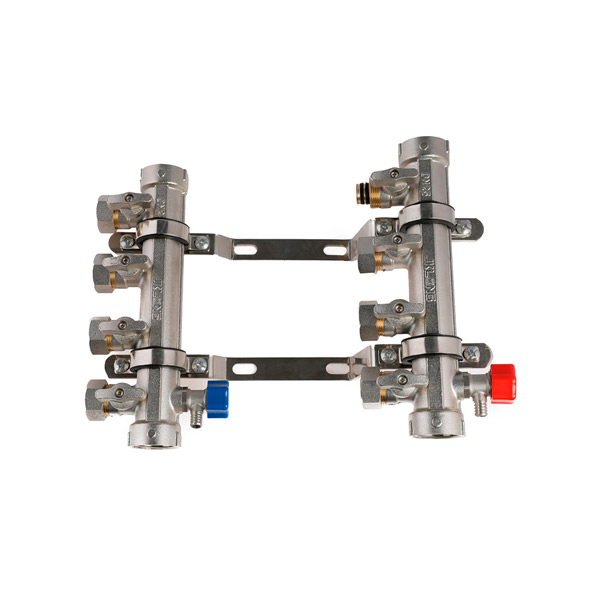

1. Determine the type of valve: gate valve, globe valve, ball valve, butterfly valve, throttle valve, safety valve, pressure reducing valve, steam trap, etc.;

2. Determine the parameters of the valve: for automatic valves, according to different needs to determine the allowable flow resistance, discharge capacity, back pressure, etc., and then determine the nominal diameter of the pipeline and the diameter of the seat hole;

3. Determine the geometric parameters of the selected valve and fittings: the length of the structure, flange connection form and size, the size of the valve height direction after opening and closing, the size and number of connected bolt holes, the entire valve external dimensions, etc.

4. Determine the nominal diameter of the pipeline connected to the valve and the connection method, to understand which is flange, threaded, welded and other connections; know which way to operate the valve, manual, electric, electromagnetic, pneumatic or hydraulic, electrical linkage or electro-hydraulic linkage it.